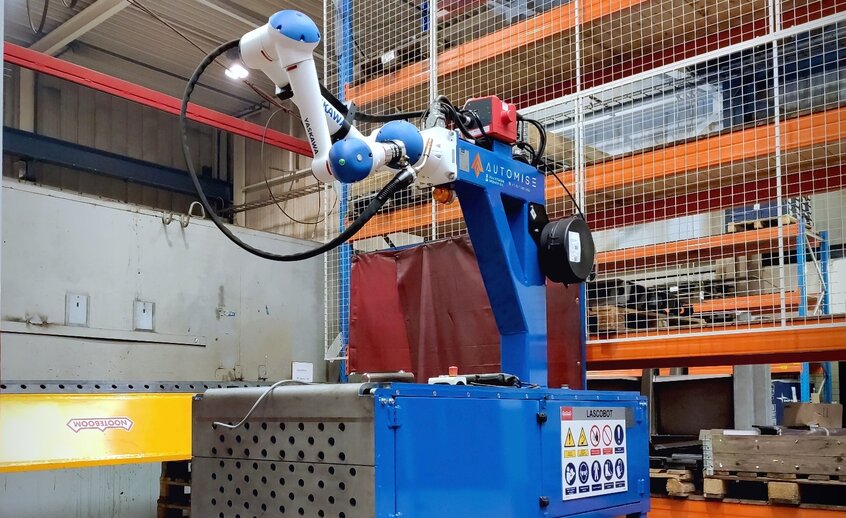

Welding cobot at Nooteboom CE marked through proper Risk Inventory and Evaluation (RI&E)

At the end of 2019 Automise B.V. integrated a Yaskawa HC10 welding robot into the production process of Nooteboom Trailers B.V. There are many questions among the cobot users about the validity of the CE marking issued by the robot supplier, the importance of a correct RI&E for cobot applications and the measures that can be taken to CE mark the entire system. This article discusses all the measures which have been taken to enable the cobot at Nooteboom Trailers to be CE marked.

- Branchen

- Metallbearbeitung

- Anwendungsmöglichkeiten

- Lichtbogenschweißen

- Kunde

- Nooteboom Trailers

- Produkte

- HC-Serie

The difference between a cobot and a robot

A cobot or co-robot is a robot designed to work together with people in a shared working environment. Cobots are integrated into the production process in such a way that they are movable and can be used in different places. Industrial robots are designed to operate independently or with limited supervision. Normally industrial robots are integrated in a fixed place in the company with the necessary fences and safety light curtains.

The system integrator of the robot application takes care of the installation, the Risk Inventory and Evaluation (RI&E), the technical file, the CE marking and the delivery. They also place all necessary fences and light barriers. Since the industrial robot does not change location and therefore the risks and associated preventions in the RI&E document do not change either, the CE marking can remain active without any problems

The CE mark of a cobot system

"The cobot is provided with a CE mark ?"

Yes that's right, the cobot is provided with a CE mark by the supplier. This CE mark only applies to the cobot arm and the associated control. The system integrator of the cobot can assemble the cobot for any application and provide the necessary tools. The integrator must comply with the Machinery Directive. For this assembled machine, a RI&E, technical file and CE marking must be drawn up, similar to an industrial robot.

The challenge? To create a reusable RI&E document for a flexible cobot system.

The preparation of a RI&E for a flexible cobot system

The main difference between a cobot and a robot is the flexible set-up on which a cobot can be integrated. At Nooteboom Trailers this is also the case, the HC10 cobot and the welding equipment are built together on a mobile work table. The cobot can be placed in several places and this has consequences for the RI&E.

Automise, in collaboration with the safety expert of Nooteboom Trailers, has drawn up an RI&E which has been assessed by an external expert. The RI&E is divided into two parts. The first part is specific to the assembled machine, the second part is specific to the environment in which the cobot may operate. For each location where the cobot is used the second part of the RI&E must be assessed

By equipping the welding robot with a number of safety features, it is possible to shield the surroundings from possible dangers. This means that the second part of the RI&E is relatively easy to set up for each location, as long as the safety features are used at each location. At Nooteboom Trailers, physical, visual and software measures were taken.

Safety provisions for the welding machine

Work instructions have been drawn up in collaboration with Nooteboom Trailers to ensure the correct use of the safety provisions. To create a shielded work area it is necessary to connect welding screens to the robot controller. When the welding screens are not connected, it is not possible to start the program of the cobot. The cables of the welding screens and the control are shielded by cable bridges on the ground to prevent tripping hazards. All connectors are protected with steel brackets. Should a collision nevertheless occur, the risk of connectors getting damaged and thus the risk of electrification is nil.

In addition to the physical safety provisions, a number of visual and software measures have also been taken. When the cobot has a collision or alarm, an orange flashing light is activated. Certified employees in the area know at that moment that they can approach the cobot thoughtfully to remedy any disruptions or collisions. The cobot arm is equipped with torque sensors. In the event of a collision with the cobot arm, the control will stop all movements. This security allows cobots to work together with people in the same environment.

This is a composite machine, which means that the risks of the mobile set-up and the welding process must also be assessed in the RI&E. During the welding process we have to deal with harmful UV radiation, due to the mandatory welding screens this risk is minimal and the employees are well protected. The welding wire is sharp and still hot after welding. Even though the cobot is equipped with torque sensors, an injury can still occur when this welding wire comes into contact with the skin. To prevent an employee from injuring himself, the welding source is configured in such a way that the welding wire is fully retracted after each weld.

To prevent an employee from being injured in the face, the working area of the cobot is divided into different zones. In the welding area, the cobot can move at the maximum speed allowed for a cobot.

At the height of the neck and face of an employee who may be working next to the cobot, the speed is limited and the welding torch must be pointed downwards. This gives the employee ample time to step aside. If it is not possible to step aside, the impact is so low that any injuries are limited. With these safety provisions, the composite cobot within its working area has been assessed as safe. In order to use the flexible cobot safely at any location, a number of conditions have been drawn up that the workplace must meet.

The RI&E for the environment of the cobot

In the first part of the RI&E, the cobot installation was assessed as a work cell. In order to be able to pick up the complete work cell and deploy it at any location, the workplace must also be assessed in the second part of the RI&E. The conditions that the workplace of the cobot must meet arise from the second part of the RI&E.

It describes, among other things, where the welding screens must be placed to create a safe workplace. This also states how much space must be free around the composite cobot installation to prevent tripping hazards and to guarantee access to the installation.

By means of a checklist, the employee can check whether the new environment in which he or she wants to place the cobot meets the requirements set in the RI&E. If this is not the case, then possible measures can be taken to be able to use the new location. Where necessary, an RI&E can be drawn up separately for this location and the associated measures can be taken.

The importance of a good RI&E for composite cobot applications

Drawing up an RI&E for a composite cobot application gives the integrator and the end user insight into the possible dangers of the installation. By thinking about these dangers and taking adequate measures, you can be sure that everything has been done to ensure the safety of the machine and the employee. This can also be demonstrated in the event of an industrial accident.

By dividing the RI&E, it is also possible with a flexible system to draw up a workable document for every location.